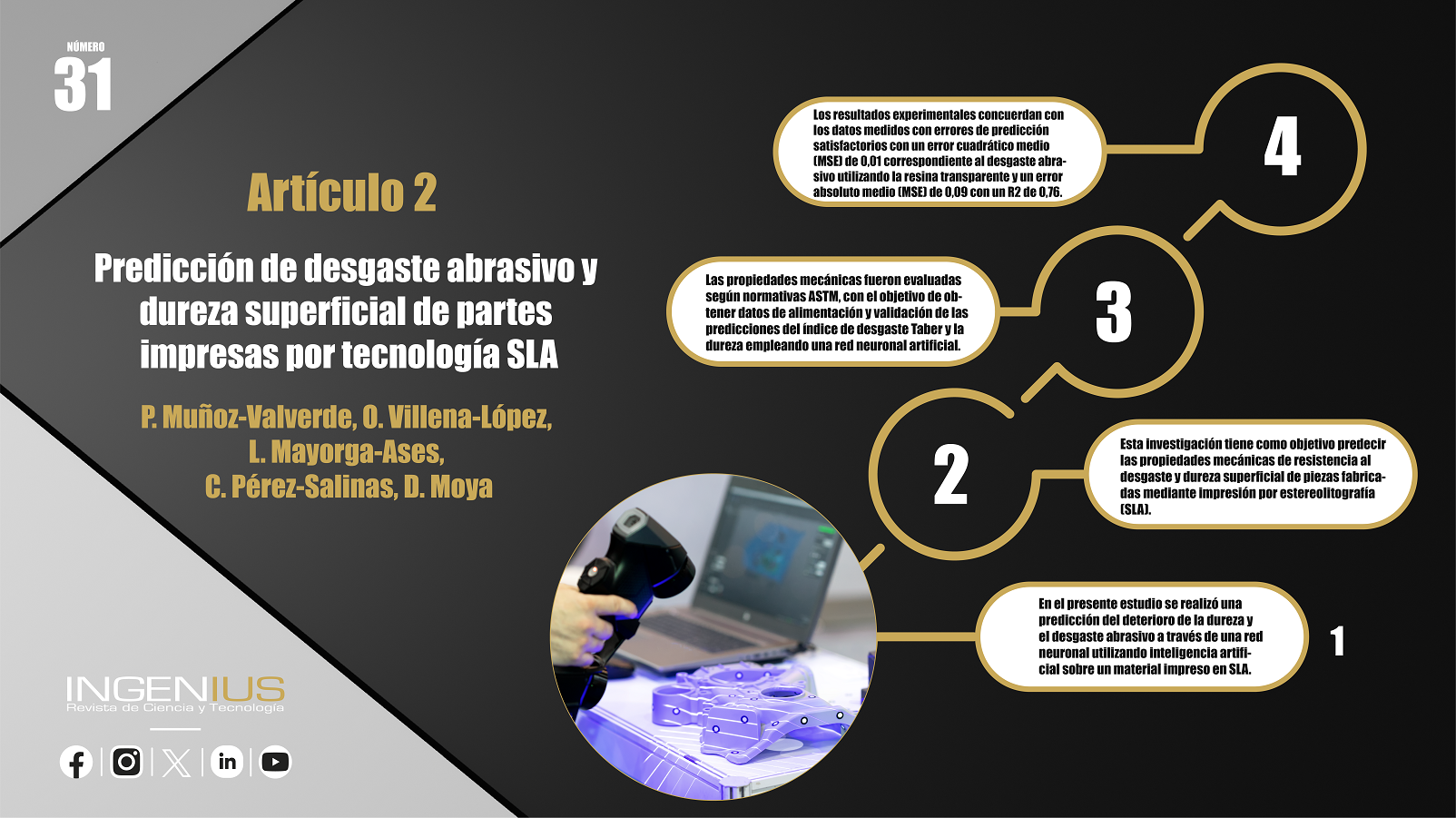

Predicción de desgaste abrasivo y dureza superficial de partes impresas por tecnología SLA

Contenido principal del artículo

Resumen

Detalles del artículo

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.

La Universidad Politécnica Salesiana de Ecuador conserva los derechos patrimoniales (copyright) de las obras publicadas y favorecerá la reutilización de las mismas. Las obras se publican en la edición electrónica de la revista bajo una licencia Creative Commons Reconocimiento / No Comercial-Sin Obra Derivada 4.0 Ecuador: se pueden copiar, usar, difundir, transmitir y exponer públicamente.

El autor/es abajo firmante transfiere parcialmente los derechos de propiedad (copyright) del presente trabajo a la Universidad Politécnica Salesiana del Ecuador, para las ediciones impresas.

Se declara además haber respetado los principios éticos de investigación y estar libre de cualquier conflicto de intereses.

El autor/es certifican que este trabajo no ha sido publicado, ni está en vías de consideración para su publicación en ninguna otra revista u obra editorial.

El autor/es se responsabilizan de su contenido y de haber contribuido a la concepción, diseño y realización del trabajo, análisis e interpretación de datos, y de haber participado en la redacción del texto y sus revisiones, así como en la aprobación de la versión que finalmente se remite en adjunto.

Referencias

T. D. Ngo, A. Kashani, G. Imbalzano, K. T. Q. Nguyen, and D. Hui, “Additive manufacturing (3D printing): A review of materials, methods, applications and challenges,” Compos. Part B Eng., vol. 143, pp. 172–196, Jun. 2018, doi: 10.1016/J.COMPOSITESB.2018.02.012.

A. Pérez, E. Romero, and A. González, “Three-dimensional printing in helthcare,” Rev. Mex. Ing. Biomédica, vol. 42, no. 2, pp. 32–48, 2021, doi: dx.doi.org/10.17488/RMIB.42.2.3.

T. Wohlers, “Rapid Prototyping & Tooling State of the Industry Annual Worldwide Progress Report Wohlers Report,” 2001. [Online]. Available: www.katzdesign.com,.

E. J. Hurst, “3D Printing in Healthcare: Emerging Applications,” J. Hosp. Librariansh., vol. 16, no. 3, pp. 255–267, Jul. 2016, doi: 10.1080/15323269.2016.1188042.

S. Mishra, “Application of 3D printing in medicine,” Indian Heart J., vol. 68, no. 1, pp. 108–109, Jan. 2016, doi: 10.1016/J.IHJ.2016.01.009.

J. W. Stansbury and M. J. Idacavage, “3D printing with polymers: Challenges among expanding options and opportunities,” Dent. Mater., vol. 32, no. 1, pp. 54–64, Jan. 2016, doi: 10.1016/J.DENTAL.2015.09.018.

A. C. Uzcategui, A. Muralidharan, V. L. Ferguson, S. J. Bryant, and R. R. McLeod, “Understanding and Improving Mechanical Properties in 3D printed Parts Using a Dual-Cure Acrylate-Based Resin for Stereolithography,” Adv. Eng. Mater., vol. 20, no. 12, pp. 1–10, 2018, doi: 10.1002/adem.201800876.

C. Mendes-Felipe, D. Patrocinio, J. M. Laza, L. Ruiz-Rubio, and J. L. Vilas-Vilela, “Evaluation of postcuring process on the thermal and mechanical properties of the Clear02TM resin used in stereolithography,” Polym. Test., vol. 72, pp. 115–121, 2018, doi: 10.1016/j.polymertesting.2018.10.018.

A. Bardelcik, S. Yang, F. Alderson, and A. Gadsden, “The effect of wash treatment on the mechanical properties and energy absorption potential of a 3D printed polymethyl methacrylate (PMMA),” Mater. Today Commun., vol. 26, no. May, p. 101728, 2021, doi: 10.1016/j.mtcomm.2020.101728.

Z. Jiang, Z. Zhang, and K. Friedrich, “Prediction on wear properties of polymer composites with artificial neural networks,” Compos. Sci. Technol., vol. 67, no. 2, pp. 168–176, 2007, doi: 10.1016/j.compscitech.2006.07.026.

A. Tura, H. Lemu, H. Mamo, and A. Santhosh, “Prediction of tensile strength in fused deposition modeling process using artificial neural network and fuzzy logic,” Prog. Addit. Manuf., 2022, doi: https://doi.org/10.1007/s40964-022-00346-y.

M. Tayyab, S. Ahmad, M. J. Akhtar, P. M. Sathikh, and R. M. Singari, “Prediction of mechanical properties for acrylonitrile-butadiene-styrene parts manufactured by fused deposition modelling using artificial neural network and genetic algorithm,” Int. J. Comput. Integr. Manuf., vol. 00, no. 00, pp. 1–18, 2022, doi: 10.1080/0951192X.2022.2104462.

U. S. Tewari, S. K. Sharma, and P. Vasudevan, Polymer tribology, vol. C29, no. 1. 1989.

B. Gupta, “3 - Friction and wear mechanism of polymers, their composites and nanocomposites,” Tribol. Polym. Polym. Compos. Polym. Nanocomposites, pp. 51–117, 2023, doi: https://doi.org/10.1016/B978-0-323-90748-4.00012-1.

E. O. Ezugwu, S. J. Arthur, and E. L. Hines, “Tool-wear prediction using artificial neural networks,” J. Mater. Process. Tech., vol. 49, no. 3–4, pp. 255–264, 1995, doi: 10.1016/0924-0136(94)01351-Z.

C. F. Pérez-Salinas, A. del Olmo, and L. N. López de Lacalle, “Estimation of Drag Finishing Abrasive Effect for Cutting Edge Preparation in Broaching Tool,” Materials (Basel)., vol. 15, no. 15, 2022, doi: 10.3390/ma15155135.

G. Radhakrishnan, C. Kesavan, V. Ramesh, and T. Anandan, “Application of artificial neural network (ANN) for predicting the wear behaviour of Al 2219-SiCp composite,” in Applied Mechanics and Materials, Trans Tech., vol. 852, 2016, pp. 397–401.

B. A. Shuvho, M. A. Chowdhury, and U. K. Debnath, “Analysis of Artificial Neural Network for Predicting Erosive Wear of Nylon-12 Polymer,” vol. 8, no. 1, 2019, doi: 10.1520/MPC20180164.

A. M and C. D, “Journal De Physique. IV: JP - Preface,” J. Phys. IV JP, vol. 11, no. 8, p. 1, 2001.

FormLabs, “Tough Tough Resin for Rugged Prototyping,” 2018.

FormLabs, “Standard Materials for High-Resolution Rapid Prototyping,” 2017.

B. Sen-Crowe, M. Sutherland, M. McKenney, and A. Elkbuli, “A Closer Look Into Global Hospital Beds Capacity and Resource Shortages During the COVID-19 Pandemic,” J. Surg. Res., vol. 260, pp. 56–63, 2021, doi: 10.1016/j.jss.2020.11.062.

S. V, “4 - Material Requirements for Plastics Used in Medical Devices,” Plast. Med. Devices, pp. 66–112, 2022, doi: https://doi.org/10.1016/B978-0-323-85126-8.00008-4.

P. Jacobs, “Fundamentals of Stereolithography,” 3D Syst. Inc., 1992.

J. H. Lee, R. K. Prud’homme, and I. A. Aksay, “Cure depth in photopolymerization: Experiments and theory,” Mater. Res. Soc., vol. 16, 2001.

A. El-Aziz, D. Saber, and A. Megahed, “Investigation and Prediction of Abrasive Wear Rate of Heat-Treated HCCIs with Different Cr/C Ratios Using Artificial Neural Networks,” Int. J. Met., vol. 15, no. 4, pp. 1149–1163, 2021, doi: https://doi.org/10.1007/s40962-020-00547-7.

A. Sagbas, F. Kahraman, and U. Esme, “Modeling and predicting abrasive wear behaviour of poly oxy methylenes using response surface methodolgy and neural Networks,” Metalurgija, vol. 48, no. 2, pp. 117–120, 2009.

N. Srivastava, G. Hinton, A. Krizhevsky, I. Sutskever, and R. Salakhutdinov, “Dropout: A simple way to prevent neural networks from overfitting,” J. Mach. Learn. Res., vol. 15, pp. 1929–1958, 2014.

K. Cho, B. van Merriënboer, D. Bahdanau, and Y. Bengio, “On the properties of neural machine translation: Encoder–decoder approaches,” Proc. SSST 2014 - 8th Work. Syntax. Semant. Struct. Stat. Transl., pp. 103–111, 2014, doi: 10.3115/v1/w14-4012.

C. Zhang, S. Bengio, M. Hardt, B. Recht, and O. Vinyals, “Understanding deep learning (still) requires rethinking generalization,” Commun. ACM, vol. 64, no. 3, pp. 107–115, 2021, doi: 10.1145/3446776.

Y. Zeng, K. Jiang, and J. Chen, “Automatic seismic salt interpretation with deep convolutional neural networks,” Proc. 2019 3rd Int. Conf. Inf. Syst. data Min., pp. 16–20, 2019.

M. Hawryluk and B. Mrzyglod, “A system of analysis and prediction of the loss of forging tool material applying artificial neural networks,” J. Min. Metall. Sect. B Metall., vol. 54, no. 3, pp. 323–337, 2018, doi: 10.2298/JMMB180417023H.

S. Sardar, S. Dey, and D. Das, “Modelling of tribological responses of composites using integrated ANN-GA technique,” J. Compos. Mater., vol. 55, no. 7, pp. 873–896, 2021, doi: https://doi.org/10.1177/0021998320960520.