|

Scientific Paper / Artículo Científico |

|

|

|

|

https://doi.org/10.17163/ings.n33.2025.02 |

|

|

|

pISSN: 1390-650X / eISSN: 1390-860X |

|

|

LIQUID LEVEL TRACKING FOR A COUPLED TANK SYSTEM USING QUASI–LPV CONTROL |

||

|

SEGUIMIENTO DEL NIVEL DE LÍQUIDO DE UN SISTEMA DE TANQUES ACOPLADO EMPLEANDO CONTROL CUASI-LPV |

||

|

Received: 13-03-2024, Received after review: 21-05-2024, Accepted:

03-07-2024, Published: 01-01-2025 |

|

Abstract |

Resumen |

|

This article proposes

a gain-scheduling procedure based on quasi-LPV modeling for a nonlinear

coupled tank system to track the liquid level with zero steadystate

error. The nonlinearities are directly represented by a parameter vector that

varies within a bounded set constrained by the

physical limits of the tank system levels. This approach enables accurate

nonlinear system modeling using a linear parameter-varying model.

State-feedback linear controllers are designed at the extreme vertices of the

bounded set. The global controller is derived as the

weighted average of local controller contributions, with the weighting

determined by the instantaneous values of the parameter vector. Two

interpolation mechanisms are proposed to implement this weighted averaging of

the linear controllers. The results confirm the effectiveness of the proposed

method in achieving accurate liquid level trackin. |

En este artículo se propone un procedimiento de programación de ganancias basado en un modelado cuasi-LPV de un sistema no lineal de tanques acoplados para seguir el nivel de líquido con error en estado estacionario nulo. Las no linealidades están representadas directamente por un vector de parámetros que varía dentro de un conjunto acotado por los límites físicos del nivel del sistema de tanques. Esto permite un modelado exacto del sistema no lineal utilizando un modelo lineal de parámetros variantes. Luego, se diseñan controladores lineales de realimentación de estado en los vértices extremos del conjunto acotado. El controlador global corresponde a un promedio ponderado de las contribuciones locales. Esta ponderación depende de los valores instantáneos del vector de parámetros. Para implementar el promedio ponderado de los controladores lineales, se proponen dos mecanismos de interpolación. Los resultados obtenidos muestran la efectividad del método. |

|

Keywords: Coupled-Tank System, Gain

Scheduling, Nonlinear Systems, Quasi-LPV, Tracking Problem |

Palabras clave: sistema de tanques acoplados, programación de ganancias, sistemas no lineales, cuasi- LPV, problema de seguimiento |

|

1,*Departamento de Gestión de Proyectos y Sistemas, Universidad Metropolitana, Caracas, Venezuela. Corresponding

author ✉: pteppa@unimet.edu.ve. Suggested

citation: Teppa-Garrán, P.; Muñoz-de Escalona, D.

and Zambrano, J. “Liquid level tracking for a coupled tank system using

quasi–lpv control,” Ingenius,

Revista de Ciencia y Tecnología,

N.◦ 33, pp. 15-26, 2025, doi: https://doi.org/10.17163/ings.n33.2025.02. |

|

1. Introduction The control of liquid levels in

tanks is widely employed in various industries, including food and beverage

production, nuclear and petrochemical plants, and the pharmaceutical sector.

Generally, interactions between tanks occur due to coupling, resulting in

nonlinear behavior [1]. Numerous control strategies have been proposed for

coupled tank systems, including Proportional-Integral-Derivative (PID)

controllers [2–4], Fuzzy control [5,6], Model Predictive Control [7,8],

Backstepping Control [9,10], Sliding-Mode Control [11,12], Fractional PID

controllers [13, 14], Robust control [15]. Active Disturbance Rejection

Control [16,17] and Two-Degree-Of-Freedom controllers [18]. Some of these

techniques rely on nonlinear system theory, which can be challenging to

implement, while others employ linearization of the system equations around

an operating point.For the

local operating range, designs based on Jacobian linearization perform effectively. However,

under significant disturbances or when faster settling times are required,

the performance of such controllers can deteriorate due to a loss of

robustness. Gain scheduling [19, 20] is a

widely adopted approach in industry for controlling nonlinear systems by

breaking down the nonlinear design problem into several smaller, manageable

subproblems where linear design tools can be applied. For instance, in robot

control, controller dynamics are adjusted in real-time based on varying

inertia and geometry. Similarly, most aircraft control laws are modified by

interpolating individually designed controllers. In recent decades, the

Linear Parameter Varying (LPV) system theory has gained prominence as a

powerful paradigm for system identification, analysis, and controller

synthesis [21–23]. This class of systems is particularly valuable as it

allows nonlinearities to be incorporated as varying parameters within a bounded

set, ensuring that the possible trajectories of the LPV system encompass all

trajectories of the original nonlinear system. When these parameters include

state vector elements, the system is referred to as quasi-LPV [24]. In this

study, the nonlinearities of the tank system model, represented by liquid

levels, are considered uncertain but constrained within the technological

limits of the equipment ([0, 30]cm). This allows for an accurate

representation of the nonlinear terms by embedding them into a quasi-LPV

model. The advantage of this approach is that it enables the design of linear

controllers using state-space techniques, ensuring zero steady-state tracking

error for constant reference inputs and guaranteeing a pole-dominant

criterion [25, 26]. Within a gain-scheduling scheme,

the control of the nonlinear coupled tank system is achieved through local

controller interpolation. Two interpolation mechanisms |

are proposed: (1) analytical

interpolation, where a system of linear equations is continuously solved to

compute the weighting factors, and (2) geometric interpolation, where the

weights of the local controllers are determined based on the Euclidean distance

to some vertex points. Analytical interpolation, initially presented in [27]

and inspired by concepts from Takagi-Sugeno fuzzy

models, is implemented in this study in a simplified form without

incorporating any fuzzy elements. Geometric interpolation, on the other hand,

offers an innovative approach in this context. While quasi-LPV theory has

been widely applied in fields such as missile guidance [28, 29] and robotics

[30, 31], its application to tank systems remains relatively unexplored

despite the significant industrial relevance of this process. The results confirm

the effectiveness of the proposed method in controlling the coupled tank

system. The article is structured as follows: Section 2 details the quasi-LPV

control design method, with a particular focus on the formulation of two

interpolation mechanisms, which are integrated within a gain-scheduled

tracking control strategy and describes the coupled tank system’s nonlinear

model. In Section 3, the quasi-LPV design method is applied to the system.

Finally, the conclusions are presented in Section 4. Notation: Bold capital letters denote matrices, while

bold lowercase letters represent vectors (i.e.

2. Materials and methods 2.1.Quasi-LPV

control design Most existing nonlinear controller

synthesis approaches focus on input-affine systems [32], which are typically

described as equation (1):

Where x The first step in the synthesis

procedure is to derive a quasi-LPV representation of the form as seen in the

equation (2): |

For the nonlinear system described

in equation (1). Here

2.2. Interpolation mechanisms Defining

For each local model, a state

vector gain Ki can be designed. The parameter vector θ(t)

is then used to construct the overall gain-scheduled controller by

interpolating the local controllers. At any given time, θ(t) can

be expressed as equation (4):

The weights αi(t) are computed by solving the system of linear

equations:

Where:

The interpolation scheme based on

the weights computed from the continuous solution of equation (5) is referred

to as analytical interpolation to distinguish it from geometric

interpolation, which will be described below. At any given time, the Euclidean

distance between the state-dependent parameter vector |

The relative contribution of the

parameter vector

Points further from the vertices

should have lower weights. Therefore, the complementary distance,

As in the analytical procedure,

the weights computed using the geometric approach continuously satisfy the

equation 2.3.Tracking a step reference input Using

the computed weights, the model in equation (2) can be approximated as a

combination of the local linear models:

The design problem now focuses on

tracking a step reference input r(t) with zero steady-state error e(t)

defined as:

Where is the controlled output.

Taking the time derivative of equation (9), for a constant reference input

yields: |

Taking the time derivative of each local

linear model

Equations (11) and (12) can be combined as:

Where:

A state feedback gain for system (13) is

constructed as:

After integrating equation (14), the actual

control signal becomes:

Using the same weights , a time-varying state feedback gain

for system (8) is constructed as:

Where: Figure 1 illustrates the implementation of

the control policy described in equation (15) for each local model, as

defined in equation (3). Additionally, Figure 2 depicts the global controller

that enables the implementation of the control law in equation (16) by

interpolating the local |

controllers, either using weights computed

analytically (equation 5) or geometrically (equation (7)). For the augmented

tracking system in equation (13), the gain

Figure 1. Local tracking control system block diagram

Figure 2. Overall tracking controller implementation

by interpolating local controllers Where P represents the desired closed-loop

poles, selected to satisfy a guaranteed pole-dominant criterion [25, 26],

based on closed-loop design requirements specified in the time domain, such

as overshoot (OS) and settling time (Ts). In light of

the above discussion, the design algorithm for implementing the interpolated

control law in equation (16) is summarized in Table 1. Table 1. Design algorithm for quasi-LPV

control

|

|

2.4.Coupled Tank

System Figure 3 depicts the coupled tank system. It

consists of a single pump and two tanks, each equipped with a pressure sensor

to measure the water level. The pump transfers water from the bottom

reservoir to the top of the system. Depending on the configuration of the

outflow valves, water can flow into the upper tank, the lower tank, or both.

This configuration is illustrated in Figure 4, where the pump output is

connected to the first tank. x1 and x2 represent the water

levels in tanks 1 and 2, respectively. The vector functions in the form of

equation (18) for the coupled tank system are derived using Bernoulli’s law

and the mass balance principle [34] and are expressed as:

Figure 3. Coupled tank system

Figure 4. Standard configuration of the coupled tank

system |

Where A1 and A2 denote the

cross-sectional areas of tanks 1 and 2, respectively. Ad1,Ad2

represent the cross-sectional areas of the corresponding orifices, g is the

acceleration on Earth due to gravity, and Kf is the

pump flow constant. The numerical values of these parameters are provided in

Table 2. Table 2. Physical parameters of the coupled tank

system

3. Results and discussion This section outlines the implementation and

evaluates the performance of the quasi-LPV control method, as summarized in

Table 1. 3.1. Quasi-LPV model The input voltage applied to the pump serves

as the control signal, while the water level in the second tank is selected

as the controlled output. Based on equation (18), the nonlinear model of the

tank system can be expressed as:

The nonlinear terms in each equation can be

reformulated as follows:

Resulting in: |

Defining

the parameter vector in (19) as:

Utilizing the numerical values from Table 2,

the quasi-LPV model in the form of equation (2) is expressed as:

The liquid levels in the tanks are considered

uncertain but vary within their physical limits, as specified in Table 2,

over the interval:

When the liquid levels in the tanks vary

within the range specified in equation (22), the parameter vector in equation

(20) will fluctuate within the rectangular bounding box:

3.2.Local linearized

models The extreme parameter combinations within the

bounding box in equation (23) yield the following vectors:

|

This results in the following set of local

linearized models:

3.3.Local controllers Using equation (25), the augmented systems in

equation (13) for each vertex are given by:

The four controller gains

The resulting dominant poles are

3.4.Interpolation

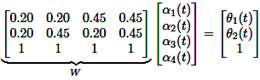

mechanisms In the analytical approach, equation (5) is

represented as the following system of linear equations: |

|

Solving this system using the pseudoinverse

matrix

For geometric interpolation, equation (7) is

implemented directly using a Matlab function block.

A straightforward Matlab function code is written

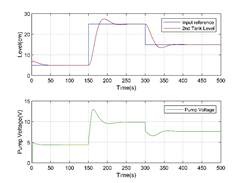

and integrated into a Simulink model, which executes the simulation. 3.5.Gain-scheduled

control implementation The gain-scheduled control strategy depicted

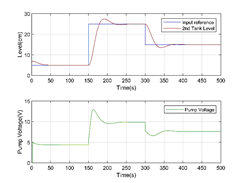

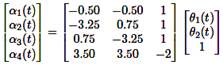

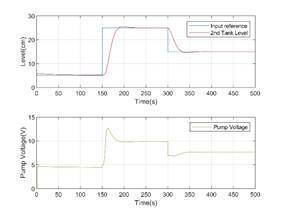

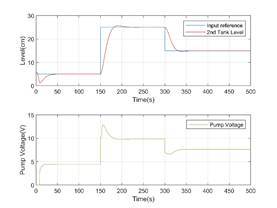

in Figure 2 was implemented. Figure 5 illustrates the liquid level response

in the second tank following a set-point change, comparing both interpolation

methods for the computed linear controllers (27).

Figure 5. Second tank closed-loop liquid level

response for analytical and geometric interpolation methods The geometric method encounters specific

issues at the start of the simulation due to its inability to provide the

required negative control action. After this initial phase, the performance

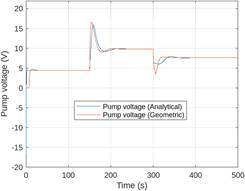

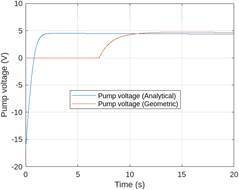

of both interpolation schemes becomes comparable. Figure 6 illustrates the control signal,

while Figure 7 focuses on the first 20 seconds of the control signal. It is

evident that when a negative control signal is required, the geometric scheme

remains at zero, confirming the issues observed at the beginning of the

simulation, as |

depicted in Figure 5. It is important to note

that the control signal provided by the pump cannot be negative, a limitation

not accounted for during the simulation when evaluating the performance of

both interpolation schemes.

Figure 6. Pump voltage control signal for analytical

and geometric interpolation methods

Figure 7. Detail of the control signal during the

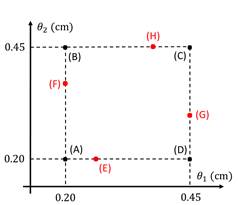

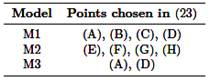

first 20 s 3.6.Further results Figure 8 illustrates the parametric bounding

box defined by equation (23). The previous results involved the

implementation of the gain scheduled controller through the interpolation

both geometric and analytical of the local controllers computed at the vertices

(A), (B), (C), and (D), based on a dominant pole criterion for the desiredOS and Ts specifications. Additionally, the

simulation permitted the control signal to take on negative values to

facilitate a comparison between the two interpolation mechanisms. The gain-scheduled controller is

implemented in this section, using various local controllers computed within

the region shown in Figure 8, as specified in Table 3. The control signal is

constrained to remain within the operational range of the pump (0-22 V), and

the desired closed-loop poles in equation (17) are selected as |

|

Figure 8. Points chosen in the parametric bounding box

(23) to compute local controllers Table 3. Points chosen in region (3) to compute local

controllers.

Model M1 utilizes the vertices of

the region, M2 computes the local controllers along the edges, and model M3

considers the extreme vertices of the region, where parameters θ1 and

θ2 take their minimum and maximum possible values. The selection of the

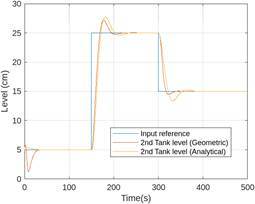

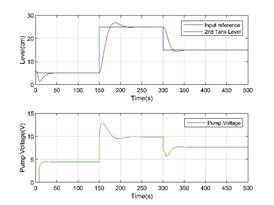

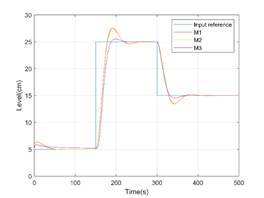

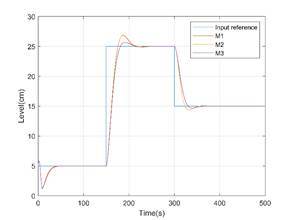

M3 model is justified by the well-known Edge Theorem [36]. Figure 9

illustrates the level in the second tank and the pump control signal using

the M1 model with analytical interpolation.

Figure 9. Second tank level and pump voltage for M1

model and analytical interpolation Figure 10 presents a similar

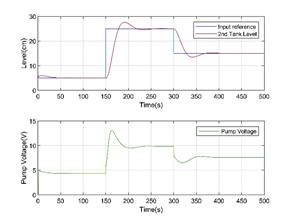

scenario employing geometric interpolation. Figures 11 ,

12 replicate the analysis for the M2 model, using analytical and geometric

interpolation mechanisms, respectively. |

Figure 10. Second tank level and pump voltage for M1

model and geometric interpolation

Figure 11. Second tank level and pump voltage for M2

model and analytical interpolation

Figure 12. Second tank level and pump voltage for M2

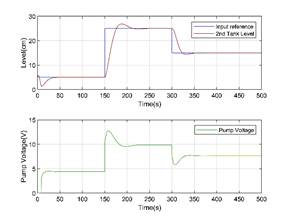

model and geometric interpolation Figures 13 and 14 display the results for the

M3 model, again using analytical and geometric interpolation, respectively.

Finally, Figures 15 and 16 compare the evolution of the liquid level in the

second tank for all three models, with analytical and geometric interpolation

considered, respectively. |

|

Figure 13. Second tank level and pump voltage for M3

model and analytical interpolation

Figure 14. Second tank level and pump voltage for M3

model and geometric interpolation

Figure 15. Second tank level for models M1, M2 and M3

using analytical interpolation

Figure 16. Second tank level for models M1, M2 and M3

using geometric interpolation |

4.

Conclusions A gain-scheduled procedure was proposed to

control a coupled tank system modeled as a quasi-LPV system. The

nonlinearities of the model are directly captured by a set of uncertain

parameters that vary within a bounded set,

constrained by the physical limits of the tank system. Extreme combinations

of the parameter vector were computed, and local linear approximations were

obtained. These approximations were then used in the state-space synthesis of

control laws to track a constant reference input. The global controller was

constructed as a weighted average of the local contributions, where the

weights depended on the instantaneous values of the parameter vector. Two

interpolation mechanisms, geometric and analytical, were employed to

determine the weighted average of the linear controllers. The geometric

method is based on the Euclidean distance between the parameter vector and

the vertices, while the analytical method involves solving a linear system of

equations using the pseudoinverse of a matrix. The geometric scheme is

simpler and generates only positive control actions, with a very short

computation time. In contrast, the analytical scheme can provide both

positive and negative control actions but requires significantly more

processing time. Simulation results demonstrated that using the two extreme

vertices (Model M3) to compute the interpolated local controllers reduces the

computational effort needed. The primary limitation of the

methodology is the challenge of accurately determining the quasi-LPV model to

capture the system’s nonlinearities, which is not an easy task for all

plants. This indicates that the proposed approach may not be universally applicable.

However, when a nonlinear plant can be effectively modeled using a linear

parameter-varying system, the method is straightforward to implement and

yields satisfactory results. Another key aspect of the method is that the

control law for designing the local controllers is not limited to closed-loop

pole assignment, as demonstrated in this article. Various state-feedback

control strategies can be employed, including those that account for

optimality, robustness, and constraints. Additionally, although the

guaranteed pole-dominant criterion is suitable for linear systems, a notable

discrepancy emerged between the design specifications and the actual

performance in the case of the nonlinear tank system. This gap was mitigated

by setting dominant real poles to improve control over the output. Ongoing work focuses on the

real-time implementation of the proposed design method and the inclusion of

state observers. Acknowledgements The authors gratefully acknowledge the

support provided by the Research Program of the Metropolitan University in

Caracas, Venezuela, under project number PG-A-13-21-22. |

|

References [1] R. Grygiel, R. Bieda, and M. Blachuta,

“On significance of second-order dynamics for coupled tanks systems,” in 2016

21st International Conference on Methods and Models in Automation and

Robotics (MMAR), 2016, pp. 1016–1021. [Online]. Available:

https://doi.org/10.1109/MMAR.2016.7575277 [2] S. K. Singh, N. Katal, and S. G. Modani, “Multi objective

optimization of pid controller for coupled-tank

liquid-level control system using genetic algorithm,” in Proceedings of the

Second International Conference on Soft Computing for Problem Solving (SocProS 2012), December 28-30, 2012, B. V. Babu, A.

Nagar, K. Deep, M. Pant, J. C. Bansal, K. Ray, and U. Gupta, Eds. New Delhi:

Springer India, 2014, pp. 59–66. [Online]. Available:

https://doi.org/10.1007/978-81-322-1602-5_7 [3] D. L. Mute, S. R. Mahapatro, and K. K.

Chaudhari, “Internal model based pi controller

design for the coupled tank system: An experimental study,” in 2016 IEEE

First International Conference on Control, Measurement and Instrumentation

(CMI), 2016, pp. 72–76. [Online]. Available:

https://doi.org/10.1109/CMI.2016.7413713 [4] M. G. Stohy, H. S. Abbas, A.-H. M.

El-Sayed, and A. G. Abo El-maged, “Parameter

estimation and pi control for a water coupled tank system,” Journal of

Advanced Engineering Trends, vol. 38, no. 2, pp. 147–159, 2020. [Online].

Available: https://doi.org/10.21608/jaet.2020.73062 [5] L. Liang, “The application of fuzzy pid

controller in coupled-tank liquid-level control system,” in 2011

International Conference on Electronics, Communications and Control (ICECC),

2011, pp. 2894–2897. [Online]. Available:

https://doi.org/10.1109/ICECC.2011.6067785 [6] A. Başçi and A. Derdiyok,

“Implementation of an adaptive fuzzy compensator for coupled tank liquid

level control system,” Measurement, vol. 91, pp. 12–18, 2016. [Online].

Available: https://doi.org/10.1016/j.measurement.2016.05.026 [7] M. Essahafi, “Model predictive control

(MPC) applied to coupled tank liquid level system,” CoRR,

vol. abs/1404.1498, 2014. [Online]. Available:

https://doi.org/10.48550/arXiv.1404.1498 [8] J. Berberich, J. Köhler, M. A. Müller,

and F. Allgöwer, “Data-driven model predictive

control: closed-loop guarantees and experimental results,” at - Automatisierungstechnik, vol. 69, no. 7, pp. 608–618,

Jun. 2021. [Online]. Available: http://dx.doi.org/10.1515/auto-2021-0024 |

[9] J. Jiffy Anna, N. E. Jaffar, and F. Riya

Mary, “Modelling and control of coupled tank liquid level system using

backstepping method,” International Journal of Engineering Research and

Technology, vol. 4, no. 6, pp. 667–671, 2015. [Online]. Available:

http://dx.doi.org/10.17577/IJERTV4IS060710 [10] J. Dai, B. Ren, and Q.-C. Zhong,

“Uncertainty and disturbance estimator-based backstepping control for

nonlinear systems with mismatched uncertainties and disturbances,” Journal of

Dynamic Systems, Measurement, and Control, vol. 140, no. 12, Jul 2018,

121005. [Online]. Available: https://doi.org/10.1115/1.4040590 [11] F.

Abu Khadra and J. Abu Qudeiri, “Second order

sliding mode control of the coupled tanks system,” Mathematical Problems in

Engineering, vol. 2015, no. 1, p. 167852, 2015. [Online]. Available:

https://doi.org/10.1155/2015/167852 [12] K. K. Ayten and A. Dumlu, “Implementation of a pid type sliding-mode controller design based on

fractional order calculus for industrial process system,” Elektronika

ir Elektrotechnika, vol.

27, no. 6, pp. 4–10, Dec. 2021. [Online]. Available:

https://doi.org/10.5755/j02.eie.30306 [13] M. Vashishth, L. S. Rai, and A. V. R. Kumar, “Liquid level

control of coupled tank system using fractional pid

controller,” 2013. [Online]. Available: https://upsalesiana.ec/ing33ar2r13 [14] P. Roy and B. Krishna Roy, “Fractional order pi control applied

to level control in coupled two tank mimo system

with experimental validation,” Control Engineering Practice, vol. 48, pp.

119–135, 2016. [Online]. Available:

https://doi.org/10.1016/j.conengprac.2016.01.002 [15] M. H. Jali, A. Ibrahim, R. Ghazali, C. C. Soon, and A. R. Muhammad, “Robust Control Approach of SISO Coupled Tank System,” International Journal of Advanced Computer Science and Applications, vol. 12, no. 1, 2021. [Online]. Available: http://dx.doi.org/10.14569/IJACSA.2021.0120123 [16] P. Teppa,

M. Bravo, and G. Garcia, “Control por rechazo activo de perturbaciones del

nivel de líquido de un sistema de tanques acoplado,” Revista Faraute de

Ciencia y Tecnología, vol. 7, no. 1, pp. 10–18, 2012. [Online]. Available: https://upsalesiana.ec/ing33ar2r16

[17] P. Teppa Garran and G. Garcia, “Design of an optimal pid controller for a coupled tanks system employing adrc,” IEEE Latin America Transactions, vol. 15, no. 2,

pp. 189–196, 2017. [Online]. Available:

https://doi.org/10.1109/TLA.2017.7854611 |

|

[18] P. Teppa Garran, M. Faggioni, and G.

Garcia, “Optimal tracking in two-degree-of-freedom control systems: Coupled

tank system,” Journal of Applied Research and Technology, vol. 21, no. 4, pp.

560–570, 2023. [Online]. Available: https://doi.org/10.22201/icat.24486736e.2023.21.4.2000 [19] W. J. Rugh and J. S. Shamma, “Research on gain scheduling,” Automatica, vol. 36, no. 10, pp. 1401–1425, 2000.

[Online]. Available: https://doi.org/10.1016/S0005-1098(00)00058-3 [20] D. Rotondo, Advances in Gain-Scheduling and Fault Tolerant

Control Techniques. Springer Cham, 2018. [Online]. Available:

https://doi.org/10.1007/978-3-319-62902-5 [21] G. S. X. Bombois, D. Ghosh and J. Huillery, “Lpv system

identification for control using the local approach,” International Journal

of Control, vol. 94, no. 2, pp. 390–410, 2021. [Online]. Available:

https://doi.org/10.1080/00207179.2019.1596316 [22] Z. GAO and J. FU, “Robust lpv modeling

and control of aircraft flying through wind disturbance,” Chinese Journal of

Aeronautics, vol. 32, no. 7, pp. 1588–1602, 2019. [Online]. Available:

https://doi.org/10.1016/j.cja.2019.03.029 [23] S. Li, A.-T. Nguyen, T.-M. Guerra, and A. Kruszewski,

“Reduced-order model based Dynamic tracking for soft manipulators:

Data-driven lpv modeling, control design and

experimental results,” Control Engineering Practice, vol. 138, p. 105618,

2023. [Online]. Available: https://doi.org/10.1016/j.conengprac.2023.105618 [24] R. Robles, A. Sala, and M.

Bernal, “Performanceoriented quasi-lpv modeling of nonlinear systems,” International Journal

of Robust and Nonlinear Control, vol. 29, no. 5, pp. 1230–1248, 2019.

[Online]. Available: https://doi.org/10.1002/rnc.4444 [25] P. Persson and K. Astrom, “Dominant pole design - a unified view

of pid controller tuning,” IFAC Proceedings

Volumes, vol. 25, no. 14, pp. 377–382, 1992. [Online]. Available:

https://doi.org/10.1016/S1474-6670(17)50763-6 [26] A. D. Mammadov, E. Dincel, and M. T.

Söylemez, “Analytical design of discrete pi–pr controllers via dominant pole

assignment,” ISA Transactions, vol. 123, pp. 312–322, 2022. [Online].

Available: https://doi.org/10.1016/j.isatra.2021.05.038 [27] P. Teppa-Garrán and J. Andrade-Da

Silva, “An analytical interpolation approach for gain scheduling control of

linear parameter varying systems,” Ciencia e Ingeniería,

vol. 30, no. 1, pp. 93–101, 2008. [Online]. Available:

https://upsalesiana.ec/ing33ar2r27 |

[28] W. Tan, A. Packard, and G. Balas, “Quasi-lpv

modeling and lpv control of a generic missile,” in

Proceedings of the 2000 American Control Conference. ACC (IEEE Cat.

No.00CH36334), vol. 5, 2000, pp. 3692–3696. [Online]. Available:

https://doi.org/10.1109/ACC.2000.879259

[29] G. Vinco, S. Theodoulis, O. Sename, and G. Strub, “Quasi-lpv

modeling of guided projectile pitch dynamics through state transformation

technique,” IFAC-PapersOnLine, vol. 55, no. 35, pp.

43–48, 2022, 5th IFAC Workshop on Linear Parameter Varying Systems LPVS 2022.

[Online]. Available: https://doi.org/10.1016/j.ifacol.2022.11.288 [30] Z. He and L. Zhao, “Quadrotor trajectory tracking based on quasi-lpv system and internal model control,” Mathematical

Problems in Engineering, vol. 2015, no. 1, p. 857291, 2015. [Online].

Available: https://doi.org/10.1155/2015/857291 [31] P. S. Cisneros, A. Sridharan, and H. Werner, “Constrained

predictive control of a robotic manipulator using quasi-lpv

representations,” IFAC-PapersOnLine, vol. 51, no.

26, pp. 118–123, 2018, 2nd IFAC Workshop on Linear Parameter Varying Systems

LPVS 2018. [Online]. Available: https://doi.org/10.1016/j.ifacol.2018.11.158 [32] H. Xie, L. Dai, Y. Lu, and Y. Xia, “Disturbance rejection mpc framework for inputaffine

nonlinear systems,” IEEE Transactions on Automatic Control, vol. 67, no. 12,

pp. 6595–6610, 2022. [Online]. Available:

https://doi.org/10.1109/TAC.2021.3133376 33] J. Stefanovski, “Feedback affinization of nonlinear control

systems,” Systems & Control Letters, vol. 46, no. 3, pp. 207–217, 2002.

[Online]. Available: https://doi.org/10.1016/S0167-6911(02)00136-6 [34] J. Apkarian, Coupled water tank experiments manual. Quanser Consulting Advanced Teaching Systems, 1999.

[Online]. Available: https://upsalesiana.ec/ing33ar2r34 [35] R. C. Dorf and R. H. Bishop, Modern Control Systems. Prentice

Hall, 2008. [Online]. Available: https://upsalesiana.ec/ing33ar2r35 [36] A. Bartlett, C. Hollot, and H. Lin,

“Root locations of an entire polytope of polynomials: It suffices to check

the edges,” in 1987 American Control Conference, 1987, pp. 1611–1616.

[Online]. Available: https://doi.org/10.23919/ACC.1987.4789571 |